GTT NO96 systems

- Kyeongsoo Shon

- Feb 4, 2021

- 1 min read

Updated: Feb 4, 2021

NO96 technology is a cryogenic liner used to contain liquefied gas at low temperatures during shipping, onshore and offshore storage, at atmospheric pressure. This technology and its evolutions equip more than 200 vessels in operation and under construction and take advantages of more than 50 years at sea.

The concept

The primary and secondary membranes are made of Invar®, a 36% nickel-steel alloy, 0.7mm thick. The primary membrane contains the LNG cargo, while the secondary membrane, identical to the primary, ensures a 100% redundancy in case of leakage. Each of the 500mm wide Invar® strakes is continuously spread along the tank walls and is evenly supported by the primary and the secondary insulation layers.

NO96 concept

NO96 evolutions: improving the thermomechanical efficiency of the system

GTT’s technologies are continually being optimised to meet the requirements of ship-owners and shipyards, while also complying with regulatory changes affecting the sector.

The perlite has been replaced by foam in NO96 L03 or by glass-wool in NO96 GW evolution. A set of reinforced boxes have also been developed in order to meet requirements for systems sustaining higher loads.

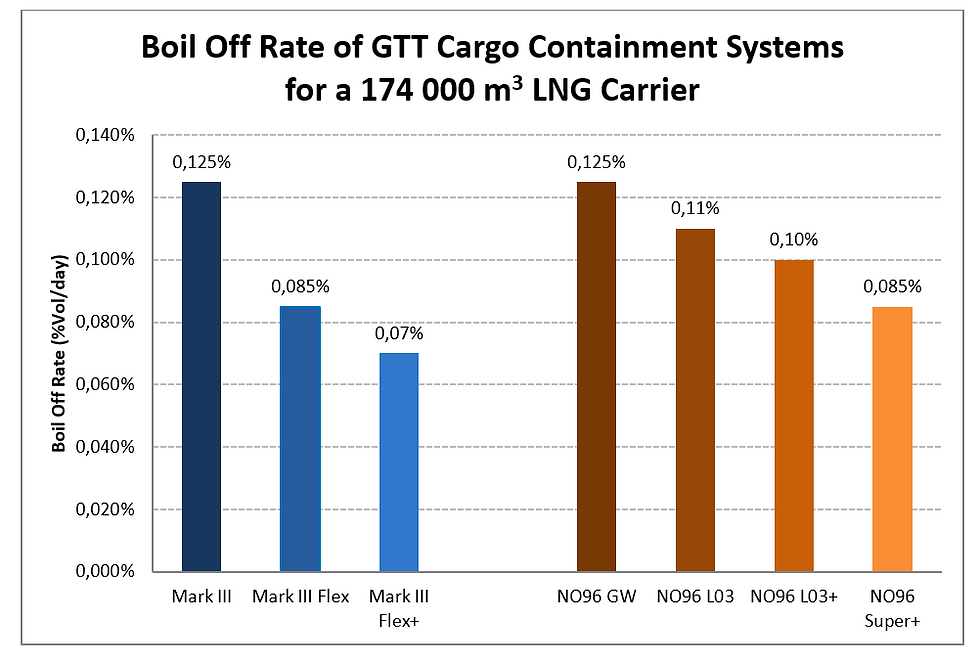

* BOR is project dependent due to vessel size, tank arrangement and reinforcements.

Comments