NO96 Super+

- Kyeongsoo Shon

- Mar 25, 2021

- 2 min read

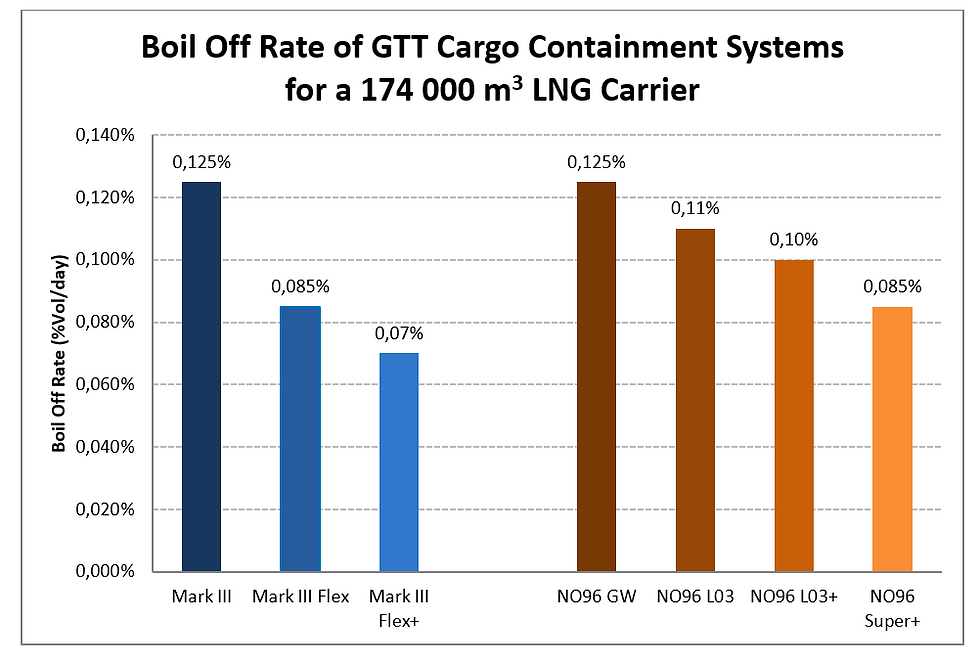

GTT membrane technologies continue to evolve based on significant feedback from operational experience, in order to meet the requirements of ship-owners and shipyards, while also complying with regulatory changes affecting the industry. GTT has introduced several new technologies in order to minimise the evaporation of the cargo during operations. As highlighted on the below graph, since 2010, the guaranteed Boil-Off-Rate (BOR) achievable with GTT technologies has been significantly reduced from 0.15%V/day down to 0.07%V/day.

Currently the actual lowest passive BOR available with NO96 system is equal to 0.10%V/d using the NO96 L03+ system. In order to complete the NO96 family offer with a guaranteed Boil Off Rate equal to 0,085%V/d GTT has recently developed a new Cargo Containment System named NO96 Super+.

This new CCS NO96 Super+ maintains the main features of the NO96 technology that have been key factors in its success, in particular the double Invar metallic membranes. As initiated with NO96 L03 and NO96 L03+ technologies, the integration of insulating R-PUF panels is further pursued to take advantage of the continuous improvement in thermal performance of R-PUF material. With NO96 Super+ system, R-PUF panels are used for the primary insulation space (Inter Barrier Space) as well for secondary (Insulation Space), for insulating purposes and to support the two metallic membranes.

The erection philosophy is identical to NO96 systems: the anchoring of the insulation panels is made with couplers to take advantage of the excellent feedback from years of use on NO96 ships. The global arrangement of panels inside the tank, the corner and special areas designs are kept identical to the sea-proven NO96 system.

Glass Wool flat joints are inserted between adjacent foam panels to optimize the thermal behaviour of the system and propose the best thermal performance. GTT has been granted with “Approval In Principle” by Bureau Veritas in September 2020. The involvement of classification societies will continue in 2021 to review for this system all the required validation studies (numerical analyses and experimental tests on components). Final class approval should be obtained by mid-2021 and this new system will then be available for newbuilding LNGC projects.

Comments